How To

How to Measure a Box / Size

The size of a corrugated box is always in the sequence length x width x depth (height).These are the inside dimensions and are used in determining the proper size of box to ensure a good fit for the product.

With the box open:

- The length is the measurement of the longest side of the rectangle

- The width is the measurement of the shorter side of the rectangle

- The depth, or height, is the measurement of the side perpendicular to the ground and/or the opening

In the case of corrugated pads or sheets, which have only two dimensions, the size is specified with the first dimension parallel to the flutes.

Flutes

Flutes are the waves that define corrugated paper/cardboard. The most common Flute sizes are, A, B, C, E and F or Microflute. We can certainly provide any of the above upon request. The letter designation does not relate to the size of the flute but to the order in which they were invented. Flute size or height refers to the number of flutes (waves) per lineal foot with C & B being most common.

B flute

- offers excellent crush resistance

- allows for high print quality

- has a lower wave height and more flutes per foot, creating a rigid surface with more points of support

- reduces storage space

C flute

- is the most popular flute size

- is thicker than the B flute

- provides excellent stacking and cushioning features

E flute

- offers the largest number of flutes per foot

- is very thin

- allows for high-quality printing

- resists crushing and other damage

Singlewall Construction

A single wall consists of a corrugated sheet between two flat sheets known as lineboards. This durable and widely used construction is also known as a doable face sheet and comes in a number of strenghts (see Tests).

Doublewall Construction

A double wall consits of two corrugated sheets and three lineboards. The corrugated sheets are usually laminated and interleaved with the lineboard. This provides extra protection and rigidity, ideal for packaging and stacking heavy items.

Tests & Strengths

Two tests measure the strength of a corrugated board: the bursting test and the edge-crush test. The bursting test evaluates the bursting strength of a board. Bursting strength is the force required to break through the board and indicates the box’s ability to withstand both internal and external pressure. Similarly, the edge-crush test evaluates the edge-crush strength of the board. Edge-crush strength is the amount of force required to crush the board’s edge and predicts the overall compression strength of the finished box.

Start with the weight of your contents to determine the strength of corrugated material you require, as indicated in the chart below:

Singlewall Corrugated Boxes:

| Maximum weight of box and contents (lbs.) | Minimum bursting test singlewall, doublewall | Minimum edge crush |

|---|---|---|

| 20 | 125 | 23 |

| 35 | 150 | 26 |

| 50 | 175 | 29 |

| 65 | 200 | 32 |

| 80 | 250 | 40 |

| 95 | 275 | 44 |

| 120 | 350 | 55 |

Doublewall Corrugated Boxes:

| Maximum weight of box and contents (lbs.) | Minimum bursting test singlewall, doublewall | Minimum edge crush |

|---|---|---|

| 80 | 200 | 42 |

| 100 | 275 | 48 |

| 120 | 350 | 51 |

| 140 | 400 | 61 |

| 160 | 500 | 71 |

| 180 | 600 | 82 |

Tier Pads

Fibreboard tier sheets and pads

Solid fiberboad can be used as the material for pads, partitions and for interior packaging. Recently, they have proven to be more cost effecive than the traditional corrugated pad.

Pallet pads and covers

Cut to the size of a pallet, they serve as pallet pads or covers forming an unbroken base or cover for product and pallet stacking. By bridging the gaps between pallet deck boards, the sheets eliminate any possible damage to product from nails and slivers of poor quality skids and the pinching of forklifts from sagging products.

Slip sheets

A sheet slightly larger than a pallet, with a scored flap on one or more sides, can be used as an expandable slip sheet. The development of gripper bars for lift trucks made it possible for the slip sheet to replace the pallet. Slip sheets are inexpensive, save four to six inches in stacking height, and can be stored in a minimum amount of space.

Tier separators

These are sheets, which are used as separators between layers of product or boxes to stabilize pallet loads.

Benefits of Fiberboard

- Always in stock

- Takes up 50% less space in your warehouse

- 100% stronger than corrugated

- More durable than corrugated

- Requires less frequent replacement

- Can be used over and over again

- Excellent material for push-pull machines

- Has a price advantage against corrugated and other types of materials

- Available in: 24-30 point for light applications and 60-80 point for heavy applications

Box Styles

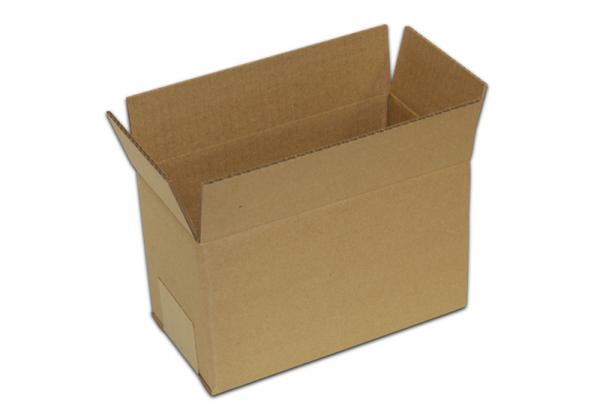

Regular slotted carton (RSC)

All flaps are the same depth and meet in the middle of the opening

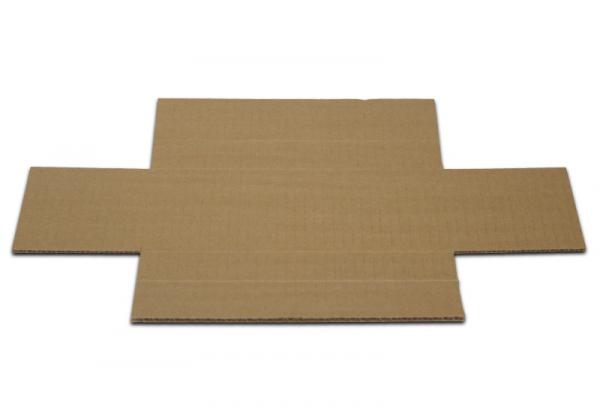

Cut out wrap (COW)

A COW is a single sheet with flaps folded to form the sides and top flaps of the box

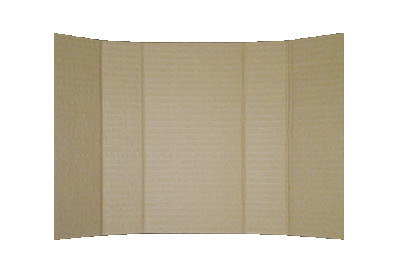

Five panel wrap (5PW)

A 5PW box is made from a single sheet that is scored and slotted into five panels – a bottom, four sides, and a closing flap

Die Cuts (DC)

Die-cut boxes are cut with a steel rule die that is mounted vertically on a wood frame

Full Telescoping Carton (FTC)

The full telescoping carton is a two-piece box, with a separate lid that slides over the main box compartment

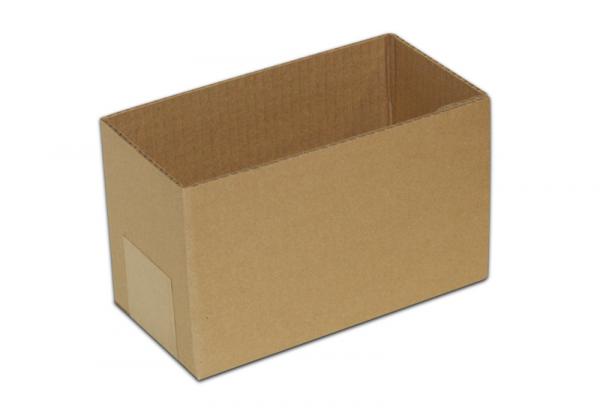

Half Slotted Carton (HSC)

Like the regular slotted carton, the half slotted carton is a single-unit box

Sleeve

A sleeve is essentially a box without ends. A scored board is wrapped to create a 3D rectangle

Scored Sheets

Just as its name implies, a scored sheet is a piece of cardboard that has been scored for easy folding

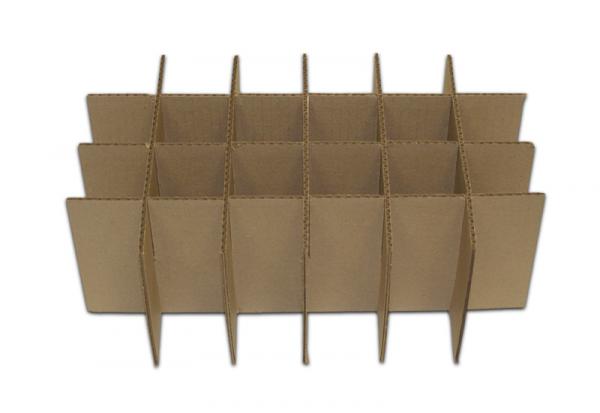

Dividers

Dividers, or partitions, are grids of corrugated board used to separate and cushion items within a larger box